A rubber gaskets factory is a specialized manufacturing facility that produces a wide variety of gasket products made from rubber materials. Rubber gaskets play a crucial role in various industries, including automotive, aerospace, plumbing, construction, and manufacturing. They are essential components that provide sealing and insulation properties, preventing the leakage of fluids or gases and ensuring the efficient operation of machinery and equipment.

Here is a detailed description of a typical rubber gaskets factory:

- Location and Facility: A rubber gaskets factory is usually located in an industrial area with convenient access to transportation and raw materials. The facility itself is equipped with specialized machinery and equipment designed for the production of rubber gaskets. It may consist of various departments, including manufacturing, quality control, research and development, and administrative offices.

- Raw Materials: The primary raw material used in a rubber gaskets factory is rubber. Different types of rubber, such as natural rubber, synthetic rubber (like neoprene, EPDM, or silicone), and various rubber compounds, are sourced from reliable suppliers. These raw materials are stored in a controlled environment to maintain their quality.

- Manufacturing Process:

- Mixing: Rubber compounds are mixed with additives and curing agents in a large mixer to create a homogeneous mixture.

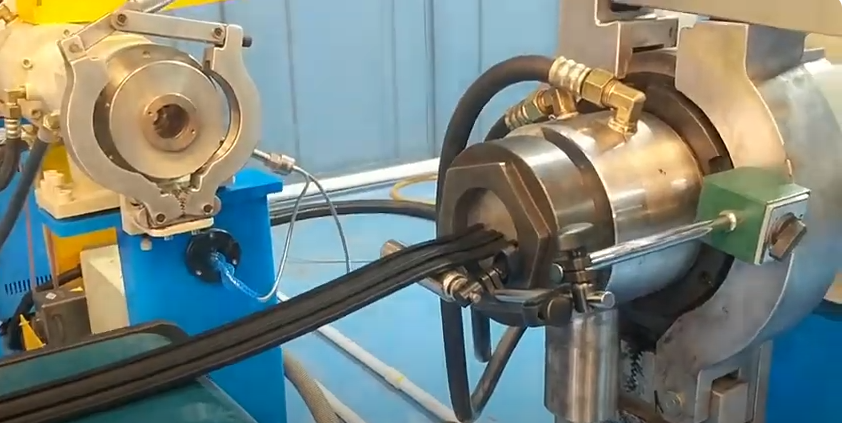

- Molding: The rubber mixture is then shaped into gaskets using various molding techniques like compression molding, injection molding, or extrusion molding.

- Curing: The molded gaskets are cured in ovens or autoclaves to achieve the desired physical properties and durability.

- Cutting and Finishing: Once cured, the gaskets are cut into specific shapes and sizes using precision cutting equipment. They may undergo further finishing processes, such as surface treatments or coatings, to enhance their performance.

- Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that gaskets meet industry standards and customer specifications.

- Product Range: A rubber gaskets factory produces a diverse range of gasket products, including:

- Flat gaskets: These are used for sealing flat surfaces and are common in applications like flanges and machinery.

- O-ring gaskets: Circular gaskets that provide an effective seal in various dynamic and static applications.

- Custom gaskets: Tailored to meet specific customer requirements, these gaskets can come in various shapes, sizes, and materials.

- Quality Assurance: Quality is paramount in the rubber gaskets industry. The factory employs skilled technicians and utilizes state-of-the-art testing equipment to ensure that gaskets meet precise tolerances for dimensions, hardness, compression resistance, and chemical compatibility. Random sampling and rigorous testing protocols are carried out to maintain high-quality standards.

- Environmental Considerations: Many rubber gaskets factories are committed to sustainability and environmental responsibility. They may implement recycling programs, reduce waste through efficient manufacturing processes, and use eco-friendly materials and technologies.

- Certifications and Compliance: A reputable factory adheres to industry standards and may hold certifications like ISO 9001 for quality management and ISO 14001 for environmental management. Compliance with safety regulations and industry-specific standards is crucial.

- Customer Relationships: Rubber gaskets factories often have close working relationships with their customers, providing technical support, custom solutions, and just-in-time delivery services to meet specific production needs.

- Research and Development: Continuous improvement and innovation are essential in the rubber gaskets industry. Research and development teams work on developing new materials, designs, and manufacturing processes to enhance gasket performance and durability.

In summary, a rubber gaskets factory is a specialized manufacturing facility dedicated to producing high-quality rubber gasket products that serve various industries by ensuring the efficient and reliable operation of machinery and equipment through effective sealing and insulation properties. These factories combine advanced technology, skilled craftsmanship, and a commitment to quality to meet the diverse needs of their customers while adhering to strict environmental and safety standards.