“Ship seals” can refer to various sealing systems and components used on ships and vessels to maintain the integrity of the hull, prevent water ingress, and ensure the safety and functionality of maritime operations. These seals play a crucial role in the maritime industry, where water-tightness and protection against environmental elements are paramount. Here’s a detailed description of some common types of ship seals:

**1. Hull Seals: Hull seals are critical to maintaining a ship’s water-tight integrity. They include various components and sealing mechanisms designed to prevent water from entering the ship’s hull. Key types of hull seals include:

- Hull Penetrations: These seals are used around openings in the hull, such as for propeller shafts, rudder stocks, sea chests, and sonar equipment. They ensure that water does not enter the ship through these openings.

- Hatch Covers: Hatch covers are used to seal cargo holds, preventing water from entering during rough seas or heavy rain. They are commonly found on cargo ships and bulk carriers.

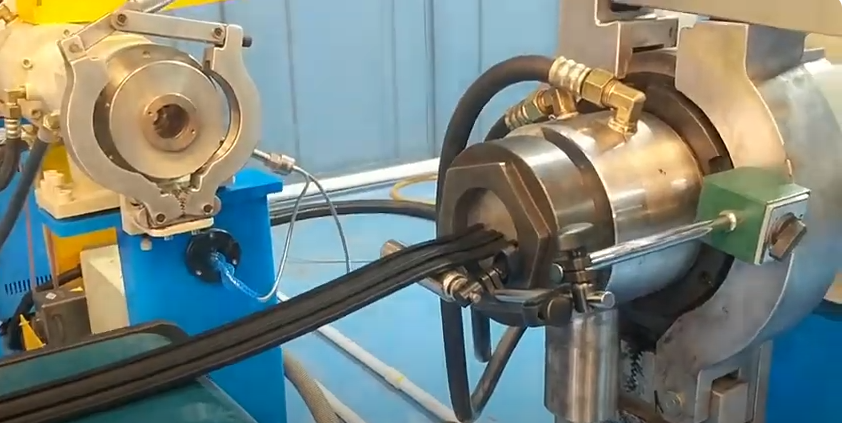

**2. Shaft Seals: Shaft seals are used to prevent water from entering the ship through the propeller shaft opening in the hull. Common types of shaft seals include:

- Stuffing Box: Traditional stuffing boxes use packing material to create a seal around the propeller shaft. Regular maintenance is required to ensure proper sealing.

- Mechanical Face Seals: These seals use mechanical components to create a watertight seal around the shaft. They are commonly used in modern ships and require less maintenance.

**3. Gasket Seals: Gaskets are used throughout ships in various applications, such as doors, hatches, and access panels. They create a seal to maintain water-tightness, prevent leaks, and protect against environmental factors.

**4. Valve Seals: Seals are used in ship valves, ensuring that fluids or gases are properly controlled without leakage. Valve seals are critical for safety and operational control in ship systems.

**5. Bulkhead Seals: Bulkheads are used to divide the ship’s interior into compartments. Seals on bulkheads ensure that, in the event of a breach in one compartment, water is prevented from flooding other sections of the ship.

**6. Duct Seals: Ships have various ventilation and exhaust ducts that require sealing to prevent the ingress of water, especially in rough sea conditions.

**7. Rubber Seals: Rubber seals are used in various ship components, including doors, windows, hatches, and access points, to provide effective sealing against water, wind, and environmental elements.

Benefits and Importance:

The proper functioning of ship seals is critical for several reasons:

- Safety: Water-tight seals help maintain ship stability and buoyancy, preventing flooding and ensuring the safety of crew and cargo.

- Environmental Protection: Effective seals prevent oil spills, pollutants, and ballast water from leaking into the marine environment.

- Operational Efficiency: Seals in propulsion systems and valves ensure the ship’s engines operate efficiently and that systems remain watertight.

- Cargo Protection: Hatch covers and other cargo hold seals protect valuable cargo from damage due to water ingress.

In conclusion, ship seals encompass a wide range of sealing systems and components that are vital for the safety, integrity, and functionality of ships and vessels. They help prevent water ingress, protect the environment, and ensure the reliability of maritime operations. Proper maintenance and regular inspections are essential to keep ship seals in optimal condition.