Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joint seals, are specialized components used in concrete pipe systems to create watertight and secure connections between concrete pipes and fittings. These seals are crucial for preventing water infiltration, maintaining structural integrity, and ensuring the long-term performance of concrete sewer, stormwater, and drainage systems. Here is a detailed description of concrete pipe seals:

Key Features of Concrete Pipe Seals:

- Material Composition: Concrete pipe seals are typically made from resilient materials with excellent sealing properties. Common materials include rubber, elastomers, or thermoplastic compounds. These materials are chosen for their durability, flexibility, and resistance to environmental factors.

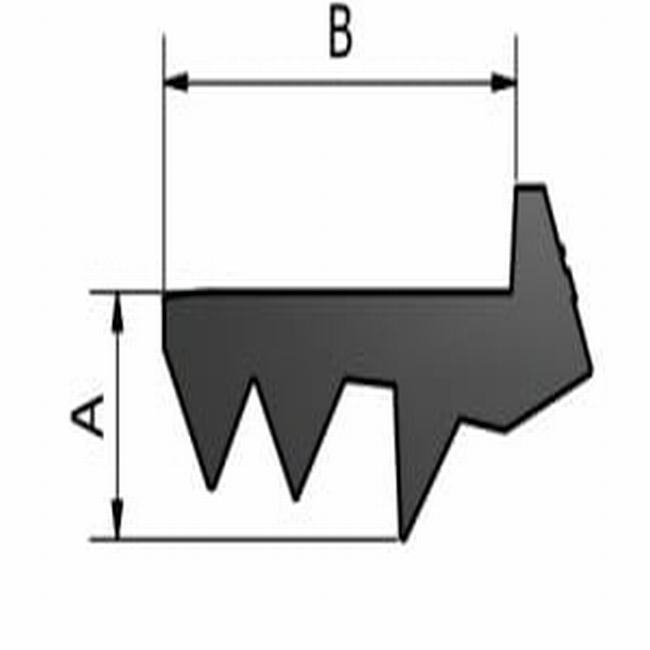

- Design Variations: Concrete pipe seals come in various shapes and designs to accommodate different pipe sizes, configurations, and joint types. The most common designs include O-ring gaskets, profile gaskets, and mechanical joint seals.

- Sealing Efficiency: Concrete pipe seals are engineered to provide a reliable and watertight seal at the joint interfaces between concrete pipes, manholes, or other concrete pipe fittings. This prevents groundwater infiltration, soil destabilization, and contamination of water sources.

- Durability: The materials used in concrete pipe seals are resistant to corrosion, chemicals, and environmental factors, ensuring a long service life without degradation.

- Compression and Flexibility: Concrete pipe seals possess a degree of compression and flexibility, allowing them to adapt to variations in pipe dimensions and settle during the pipe’s lifespan without losing their sealing effectiveness.

- Ease of Installation: Most concrete pipe seals are relatively easy to install. They are typically placed in the joint groove or cavity between the pipes, creating a snug and watertight fit.

Advantages and Applications:

- Watertight Sealing: Concrete pipe seals are vital for preventing water infiltration into the pipe system. This is essential for maintaining the integrity of sewage, stormwater, and drainage systems, preventing soil erosion, and minimizing the risk of contamination.

- Structural Integrity: These seals contribute to the structural stability of the pipeline by preventing soil erosion around the pipes and maintaining the proper alignment of pipes and fittings.

- Environmental Protection: By preventing water and wastewater leaks, concrete pipe seals help protect the environment from pollutants and contaminants that may be present in the wastewater.

- Longevity: The durable materials used in concrete pipe seals ensure a long service life with minimal maintenance requirements.

- Versatility: Concrete pipe seals are used in various applications, including municipal sewer systems, stormwater management, irrigation, culverts, and industrial pipelines.

Installation and Maintenance:

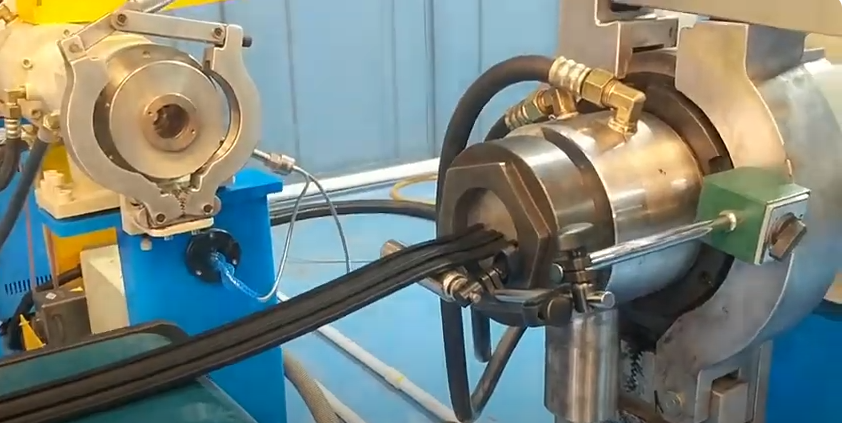

Installing concrete pipe seals involves placing the gasket or seal in the joint cavity and ensuring proper alignment between the pipes or fittings. Proper installation techniques and torque specifications provided by the manufacturer must be followed to ensure a secure and watertight seal.

Maintenance typically involves periodic inspections to check for signs of wear or damage, especially in high-load or harsh environmental conditions. Damaged seals should be promptly replaced to maintain the system’s integrity.

In summary, concrete pipe seals are essential components of concrete pipe systems, ensuring watertight, durable, and environmentally sound connections between pipes and fittings. Their effectiveness in preventing water infiltration and maintaining structural integrity makes them crucial in various infrastructure and wastewater management applications. Proper installation and maintenance are key to maximizing their performance and longevity.