Aluminum rubber, also known as aluminum rubber sheet or aluminum rubber composite, is a material that combines aluminum with rubber to create a versatile and flexible composite material. This material is engineered to take advantage of the beneficial properties of both aluminum and rubber, making it suitable for various applications. Here’s more information about aluminum rubber:

Composition:

- Aluminum: Thin sheets or layers of aluminum are typically used in aluminum rubber composites. Aluminum is known for its lightweight, excellent thermal conductivity, and corrosion resistance. These properties make it suitable for specific applications, such as heat exchange or protection against electromagnetic interference (EMI).

- Rubber: The rubber component in aluminum rubber composites is often made from synthetic or natural rubber materials. Rubber contributes to the flexibility, resilience, and vibration damping characteristics of the composite.

Key Properties and Applications:

- Thermal Insulation: Aluminum rubber composites can be used as thermal insulation materials due to the reflective properties of aluminum. They are used in applications where heat needs to be reflected or controlled, such as in automotive engine compartments, HVAC systems, or industrial insulation.

- EMI Shielding: The conductivity of aluminum makes it effective in shielding against electromagnetic interference (EMI). Aluminum rubber composites are used in electronic devices, computer equipment, and sensitive instruments to protect against EMI.

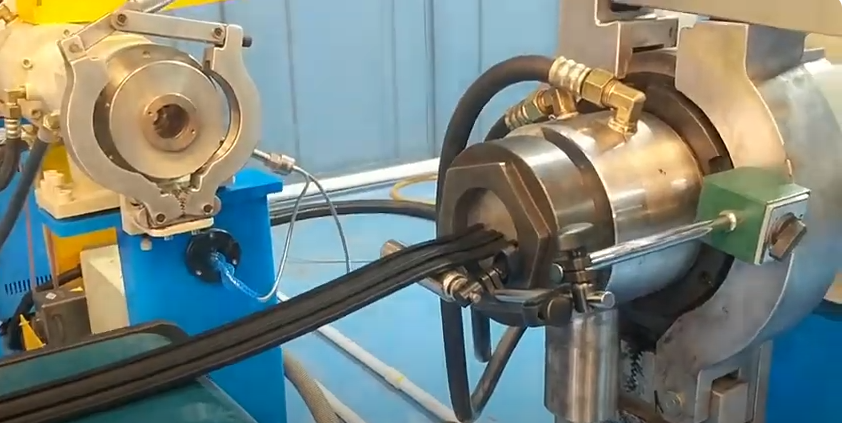

- Vibration Damping: Rubber’s ability to absorb vibrations and shock makes aluminum rubber composites suitable for applications where vibration control is important, such as in machinery mounts or automotive suspension systems.

- Gaskets and Seals: The flexibility and resilience of rubber combined with the sealing properties of aluminum make these composites useful for creating gaskets and seals. They are used in various industries to prevent leaks, such as in automotive engines and HVAC systems.

- Noise Reduction: Aluminum rubber composites can also provide acoustic insulation by dampening noise and vibration. They are used in soundproofing applications, including automotive interiors and building construction.

- Corrosion Resistance: The aluminum layer in the composite provides corrosion resistance, making these materials suitable for outdoor and marine applications.

Installation and Customization:

Aluminum rubber composites can be customized to meet specific application requirements. They are available in various thicknesses and configurations. Installation methods depend on the intended use, but typically, they are cut to size and adhered, bolted, or clamped into place.

In summary, aluminum rubber composites are versatile materials that combine the properties of aluminum and rubber to serve various functions, including thermal insulation, EMI shielding, vibration damping, sealing, and noise reduction. Their ability to be tailored to specific requirements makes them valuable in a wide range of industries and applications.