EPDM (Ethylene Propylene Diene Monomer) rubber seals are widely used in various industries for their excellent weather resistance, durability, and sealing properties. These seals are made from a synthetic rubber compound known as EPDM, which offers several advantages:

- Weather Resistance: EPDM rubber seals are highly resistant to UV rays, ozone, and extreme weather conditions, making them ideal for outdoor applications. They do not degrade or crack when exposed to sunlight and other environmental factors.

- Chemical Resistance: EPDM rubber is resistant to a wide range of chemicals, including acids, bases, and some solvents. This property makes it suitable for use in applications where exposure to chemicals is a concern.

- Temperature Resistance: EPDM rubber has excellent high and low-temperature resistance. It can withstand both extreme heat and cold without losing its elasticity or structural integrity.

- Waterproofing: EPDM rubber seals are commonly used for waterproofing applications. They create a tight, durable seal that prevents water and moisture from penetrating joints and gaps.

- Durable: EPDM rubber has a long service life and is known for its durability and low maintenance requirements. It can resist cracking, tearing, and abrasion, ensuring a reliable seal over time.

- Electrical Insulation: EPDM rubber is an excellent electrical insulator, which makes it suitable for various electrical applications and cable sealing.

EPDM rubber seals find applications in a wide range of industries and products, including:

- Automotive: EPDM seals are used in automotive weatherstripping, gaskets, and hoses due to their ability to withstand exposure to engine fluids and temperature fluctuations.

- Construction: They are used for sealing doors, windows, and roofing to prevent water and air infiltration.

- HVAC (Heating, Ventilation, and Air Conditioning): EPDM gaskets and seals are used in HVAC systems to create airtight and watertight connections.

- Electrical: EPDM rubber is used to seal electrical enclosures and provide insulation for wires and cables.

- Marine: EPDM rubber is used in boat and shipbuilding for gaskets, seals, and components exposed to saltwater and harsh marine environments.

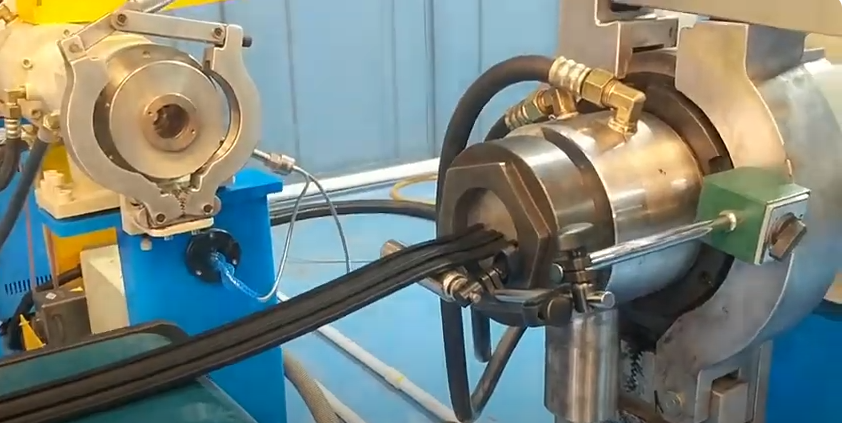

- Industrial Equipment: EPDM seals are used in various industrial equipment, including pumps, valves, and machinery, where sealing against fluids or gases is critical.

- Medical: EPDM rubber is used in medical devices and equipment due to its biocompatibility and resistance to sterilization methods.

EPDM rubber seals are available in various shapes and sizes, including O-rings, gaskets, strips, and custom-molded parts, to suit the specific needs of different applications. They are a versatile choice for sealing and protecting against environmental factors and are valued for their reliability and longevity.